024, Moving Bed Biofilm Reactor (MBBR) technology continues to establish itself as one of the most effective and versatile wastewater treatment systems available. Environmental engineers frequently rely on this method for a wide range of applications, including municipal wastewater treatment, industrial effluent, and even aquaculture systems. Central to the success of MBBR systems is the mbbr bio media, a crucial component that supports the growth of biofilm, which is essential for breaking down organic materials and treating wastewater efficiently.

This article will explore how MBBR bio media functions, its advantages in modern wastewater treatment, and how it compares to other biofilm technologies.

How MBBR Bio Media Works

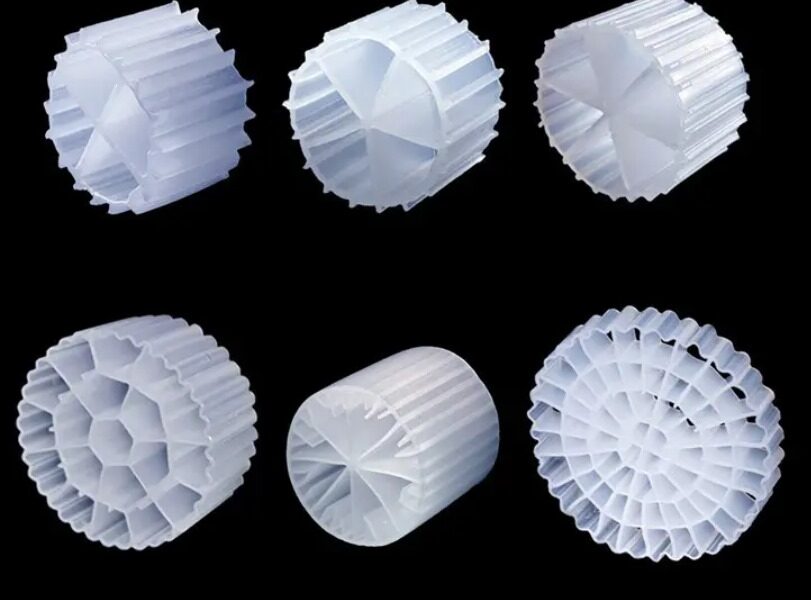

At the heart of the MBBR system lies its bio media, typically small, floating plastic carriers with high surface area. These carriers provide a physical platform for biofilm formation, enabling the growth of microorganisms that break down organic materials and nutrients in wastewater. MBBR bio media is usually designed with specific shapes and structures that increase its surface area, thus promoting efficient biofilm development and maximizing biological activity.

1. Biofilm Formation

MBBR bio media promotes the growth of microorganisms on its surface. These microorganisms form biofilms, a thin layer of bacteria and other microbes that adhere to the media. The biofilm plays a critical role in biodegradation, as the microorganisms within it metabolize organic contaminants and nutrients, transforming them into less harmful substances such as carbon dioxide, water, and biomass.

2. Continuous Movement

In an MBBR system, the bio media is suspended and continuously moves within the reactor, usually by the agitation from aeration or water flow. This movement helps ensure that the media remains in constant contact with the wastewater, providing optimal conditions for organic matter removal. It also aids in preventing the overgrowth of biofilm, which could otherwise reduce the system’s efficiency.

3. High Surface Area for Growth

The unique design of MBBR bio media provides a high surface area-to-volume ratio. This increased surface area is essential for hosting a large population of microorganisms, improving the rate of biological reactions. The more surface area available, the more biofilm can form, and the greater the system’s capacity to treat wastewater.

Advantages of MBBR Bio Media

MBBR bio media offers numerous advantages for wastewater treatment, making it a preferred choice for environmental engineers worldwide.

1. Scalability and Flexibility

One of the most significant benefits of MBBR systems is their scalability. MBBR bio media can be used in systems of varying sizes, from small community wastewater treatment plants to large municipal installations. The media itself is modular, meaning that the volume of bio media in a reactor can be adjusted based on the system’s treatment requirements. This flexibility makes MBBR ideal for upgrading existing systems or scaling treatment capacity as demands grow.

2. Compact Design

MBBR systems, due to the bio media’s high treatment capacity, tend to have a much smaller footprint compared to conventional wastewater treatment methods such as activated sludge systems. The compact design is especially beneficial for installations in urban environments or areas where land is limited. With the ability to process high volumes of wastewater in a relatively small space, MBBR is an attractive option for both retrofits and new installations.

3. Low Energy Consumption

In MBBR systems, energy consumption is often lower than in other biological treatment methods. This is primarily due to the absence of the need for constant sludge recycling, which is required in systems like activated sludge processes. Furthermore, the continuous movement of the bio media reduces the likelihood of clogging or over-accumulation of biomass, which can be a common problem in other biofilm technologies. This low-energy requirement makes MBBR a cost-effective and sustainable solution for wastewater treatment.

4. Efficient at Handling Shock Loads

One of the operational advantages of MBBR bio media is its ability to handle shock loads — sudden increases in pollutant levels or flow rates. Due to the constant presence and high concentration of biofilm on the media, the system can quickly adapt to changes in influent conditions, ensuring stable performance without significant operational disruptions.

5. Reduced Sludge Production

Compared to conventional activated sludge processes, MBBR systems produce significantly less sludge. Since the biofilm adheres to the media, much of the biological activity occurs on the surface of the media, leading to lower biomass in suspension. This reduction in sludge production minimizes the need for sludge handling and disposal, reducing operational costs and environmental impact.

Comparison to Other Biofilm Technologies

While MBBR bio media provides clear advantages in many applications, it’s essential to understand how it compares to other biofilm technologies commonly used in wastewater treatment.

1. MBBR vs. Trickling Filters

Trickling filters are one of the earliest biofilm-based wastewater treatment methods. In this system, wastewater is sprayed over a bed of media, where biofilm grows and degrades the organic matter. While trickling filters have been widely used for decades, MBBR systems offer several advantages:

- Footprint: MBBR systems are more compact, requiring less land compared to trickling filters.

- Maintenance: MBBR systems are generally easier to maintain since the bio media continuously moves and does not require cleaning or replacement as often as trickling filter media.

- Flexibility: MBBR can handle variable loads more efficiently, while trickling filters may struggle to adapt to sudden changes in flow or pollutant levels.

2. MBBR vs. Integrated Fixed-film Activated Sludge (IFAS)

IFAS technology combines the benefits of both suspended growth (activated sludge) and attached growth (biofilm) systems by introducing bio media into an activated sludge system. While IFAS has its advantages, such as enhanced nutrient removal and the ability to retrofit existing plants, MBBR systems still hold several benefits:

- Operational Simplicity: MBBR does not require the complex balancing of suspended and attached growth processes, simplifying the system’s operation.

- Sludge Management: MBBR systems typically produce less sludge compared to IFAS, leading to lower operational costs.

- Energy Efficiency: IFAS systems can require more energy due to the need for aeration and maintaining activated sludge processes, whereas MBBR systems are more energy-efficient.

3. MBBR vs. Membrane Bioreactors (MBR)

Membrane bioreactors (MBR) are another popular wastewater treatment technology that uses membrane filtration in combination with biological treatment. MBR systems are highly effective at removing contaminants but are often associated with high energy consumption and maintenance due to membrane fouling. In contrast:

- Energy Efficiency: MBBR systems consume less energy than MBR systems, which need constant aeration and membrane cleaning.

- Cost: MBR systems have higher capital and operational costs compared to MBBR, making the latter more economical, especially for smaller installations.

- Maintenance: MBR systems require more frequent maintenance and cleaning due to membrane fouling, whereas MBBR systems are easier to manage.

Conclusion

As the demand for efficient and sustainable wastewater treatment solutions grows, MBBR bio media continues to play a crucial role in modern treatment technologies. With its high surface area, scalability, and ability to handle variable loads, MBBR bio media offers several advantages over traditional systems. Compared to other biofilm technologies, MBBR stands out for its operational simplicity, low energy consumption, and reduced sludge production.

For environmental engineers seeking cost-effective and adaptable wastewater treatment solutions, MBBR bio media remains one of the most viable options for 2024 and beyond.